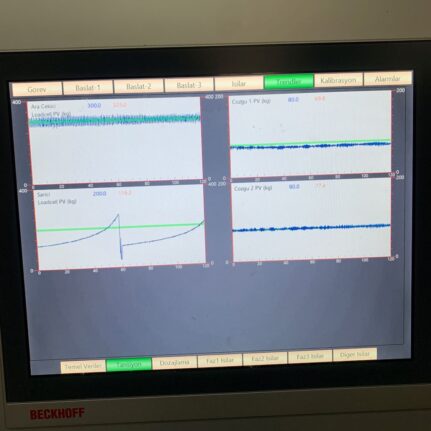

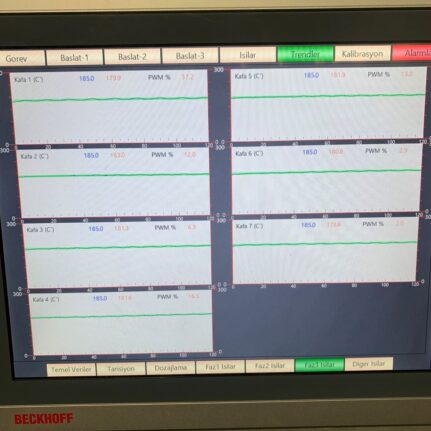

The work was carried out in accordance with the company's requirements. The excessive waste occurring in the existing production lines was examined, and areas for improvement were identified for the new line. Accordingly;

- Automatic screw control

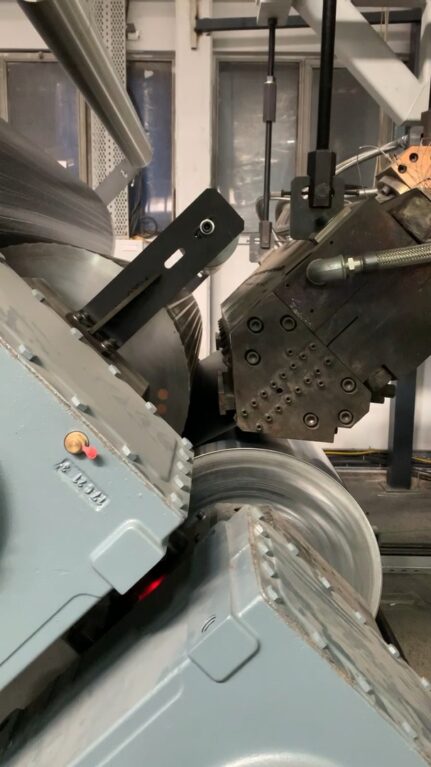

- Use of tension-controlled film warp lines

- Reusing edge scraps by breaking them off

- By developing an automatic winding system in the winding section, the discrepancies in coil lengths will be prevented

- Preventing material losses caused by operator delays

Definitive solutions were provided in areas such as these.

From raw material loading to calender control, from heat regulator control to winding equipment control, all equipment was designed to operate from a central control system.